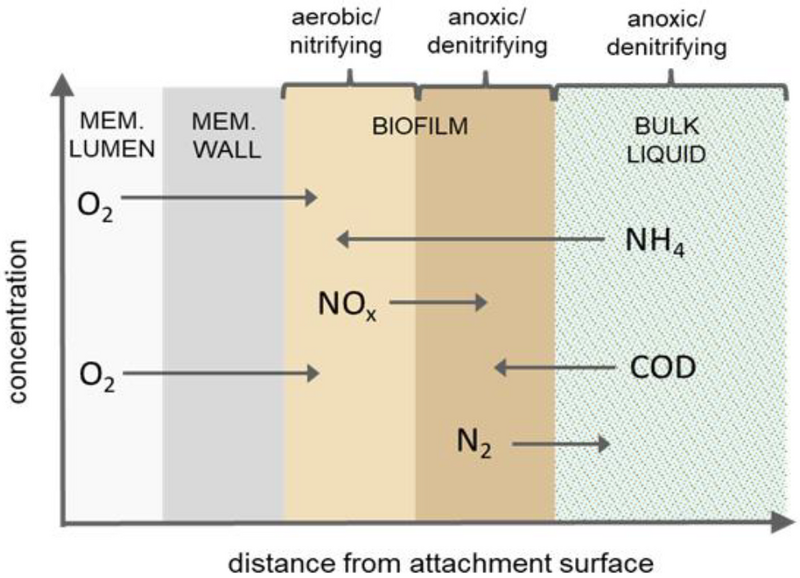

The Membrane Aerated Biofilm Reactor (MABR) is an innovative technology based on the proven MBR technology. The MABR reactor is structurally identical to the MBR rector, but its use is completely different. The MABR reactor is inserted into the activation tank of a wastewater treatment plant where it functions as a biofilm nitrification and denitrification reactor with direct oxygen supply through the membrane to the biofilm by diffusion (figure). As a result, nitrification takes place in the inner layer of the biofilm and denitrification in the outer layer. The MABR reactor can be installed in the denitrification section of the WWTP.

Due to the direct supply of oxygen to the biofilm for nitrification, the total air demand in the WWTP is reduced, thus saving energy for its supply. The MABR reactor also produces excess biomass, rich in both nitrifying and denitrifying bacteria. This stabilises the nitrogen removal process throughout the plant.

Benefits

- Intensification of N-removal (increase 50 % capacity in existing tanks)

- Process stability (biofilm is resistant to overloading – hydraulic and substances)

- Easy solution (MABR reactor installed into existing tanks)

- Energy savings

- Oxygen transfer is 4 times more effective than fine bubble aeration, energy savings for aeration is up to 50 %

- Reducing of energy consumption for pumping (lover return sludge and internal recirculation)

- Lower carbon footprint